PIPE HAULING

SOUTH SUMATERA – WEST JAVA

GAS PIPELINE PROJECT PHASE II – OFFSHORE

(Learning & Sharing)

INTRODUCTION

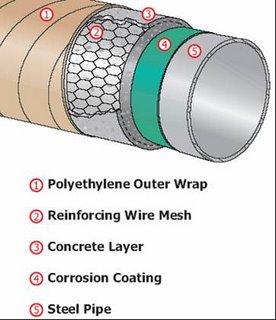

Concrete coating pipe is developed to provide:

- Sub sea stability (negative buoyancy)

- Prevention of damage (mechanical damage)

- No trenching is required

- Less steel is required

- Logistic activities for SSWJ II Offshore would be effective and efficient.

- Best Preparation of Man Power and Equipment.

- Best support for the construction / installation activity both at near shore and offshore construction areas.

- Handling of coated pipes would be in best management at coating plant - Bintan and transportation to construction site.

MAN POWER

QA/QC Engineer :

- to inspect Coated pipes by visual inspection

- to collect and record QC documents

HSE Officer :

- to asist the Bintan Coordinantor in maintaining the activity of the transportation in order to meet the HSE requirements.

Logistic Officer :

- to coordinate and monitor the Fabrication of Coating Pipe schedule

- to report to the Procurement and Project Manager and Construction Manager regarding the overall Fabrication progress and Transportation to construction areas

- to coordinate barge load out in order to meet the pipelay schedule

- to communicate with the Laying Barge regarding the offshore position

- to supervise the loading of the pipes

- to coordinate barge load out in order to meet the pipelay schedule

- to communicate with the Laying Barge regarding the offshore position

- to supervise the loading of the pipes to report to the Bintan Operational Coordinator regarding all of the barging activity and progress

OPERATIONAL OVERVIEW

- Loading operations at coaters stock pile

- Trucking to wharfside

- Pre-loading survey

- Tallying operations

- HSE/OHSI Briefings

- Loading operations at wharfside

- Stevedoring at wharfside

- Lashing,securing and dunnaging onboard barges

- Barging operations

WORK FLOW

LOADING OPERATORS @ COATERS STOCKPILE

- 2 units of 50T hydraulic boom cranes with crane operators

- 2 sets of stevedores

- 1 foreman

- 6 trucks shunting cargo between stockpile area and wharfside, each truck carrying 3 pipes

MATERIALS & EQUIPMENTS

- All materials used to secure and lash the cargo are certified and all certificates are to be issued

- Loading equipment also to be inspected and certified prior to each load out. All certificates are to be valid or have to be renewed.

- 1 X 125T Wharfside Crane

- 2 X 50T Yard Crane

- Spreader bars @ 22T

- Lashing wires @ 20mm

- Turnbuckles @ 17T

- Shackles @ 17T

- Wire clips @ 6T

- Tarpauline

- Dunnage

- Rubber hose

- Rubber tubes

- Lifting hooks @ 12T

- Lifting belts @ 20T

SURVEYORS

- All pre-loading, On-hire, lashing & securing surveys to be carried out by registered independent surveyors.

HSE / OHSI

- All safety procedures to be scrutinised and monitored by fully certified HSE personnel.

- Ensuring all PPE in place and maintained.

TUG & BARGES

- Various Tug & Barge sizes to be utilized.

- All Tug & Barges have valid registration certificates and class certification.

ONSHORE / NEARSHORES BARGES

Barges for transporting to onshore/nearshore:

- Hafar 218

- Hafar 231

- ADMI

- DMB 8

DMB 88 Lay Barge

OFFSHORE BARGES

Barge for transporting to Offshore:

- CSF 2303

- CSF 2301

- CSF 2302

- CSF 2501

- MANN 2101

- MANN 2701

- CSF 2702

PLB 132 Lay Barge

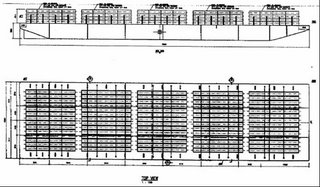

STOWAGE PLAN

STOWAGE PLAN (Lashing & Cover)

COMMUNICATION SYSTEM